mechanical properties on food

In recent years, there has been a growing interest in the physical properties of food. A number of books and reviews dealing specifically with the subject have been published. Some physical properties of food such as viscosity in fluid flow, particle size in size reduction, thermal properties in heat transfer, diffusivity in mass transfer, etc.

Mechanical Properties on Food

Mechanical properties are the properties that determine the behavior of a food material when in contact with an external force. Mechanical properties can be used for processing (eg transport, size reduction) and consumption (texture, mouthfeel). The forces acting on the material are usually expressed as stress, i.e. the intensity of the force per unit area (N/m2 or Pa). Dimensions and units of stress are similar to pressure. Very often, but not always, the response of a material to stress is deformation expressed as strain. Strain is usually expressed as a dimensionless ratio, such as elongation as a percentage of the original length. The relationship between stress and strain is the subject of a science known as rheology.

Elastic Deformation

Elastic deformation appears instantaneously when there is pressure and disappears instantly by releasing the pressure. For some materials, strain is proportional to stress, at least for moderate deformation values. The elastic deformation is defined by Hooke’s law as:

E = Stress/Strain = (F/A0)/(∆L/L0)

E = Modulus Young , Pa

F = Force, N

A0 = Initial surface area, m2

ΔL = Length increase, m

L0 = Initial length, m

Plastic Deformation

Plastic deformation does not occur as long as the stress is below a limit value known as yield stress. Plastic deformation is permanent, that is, the workpiece does not return to its original size and shape when the stress is removed.

Viscous Deformation

Deformation (flow) that occurs instantaneously with pressure and is permanent. The strain rate is proportional to the stress.

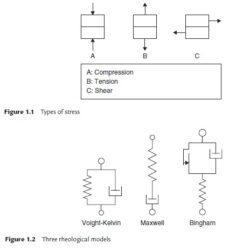

Stress types are classified according to the direction of the force in relation to the material. Normal stress is the stress that acts in a direction perpendicular to the surface of the material. Normal stresses are compressive forces if they act on the material and tensile forces if they act away from it. Shear stress acts in a parallel (tangential) direction to the surface of the material. The increase in deformation of a body under constant pressure is called creep. The decay of stress with time under constant strain is called relaxation.

Rheology Model

The stress-strain relationship in foodstuffs is usually complex. It is therefore useful to describe the actual rheological behavior of food with the help of simplifications such as drawing models. The models are constructed by connecting ideal elements (elastic, viscous, frictional, breaking, etc.) in series, parallel or a combination of both. Physical models are useful in the development of mathematical models (equations) for the description and prediction of the rheological behavior of complex foods.

Contributor: Daris Arsyada

Reference:

Berk, Zeki. 2008. Food Process Engineering and Technology. United States of America: Elsevier

Leave a Reply

Want to join the discussion?Feel free to contribute!