air circulation design in indoor parking space

In the current era of rapidly growing development, the construction of large buildings such as hotels, malls, offices and industries is increasing. In the construction of these facilities, there are many things that must be considered for the comfort and the safety of the users.

In this article, we will highlight the design of the indoor parking lot, which is a location that is quite risky for its users because of the accumulation of gas emissions from motorized vehicles parked in that place and the danger of a fire, considering that every parked vehicle stores fuel.

Fire incidents in indoor parking lot have occurred repeatedly and have become a special concern during the design process. When a fire starts, the air ventilation system from inside the room must properly remove smoke and gases from the parking space, and ensure the evacuation process of people inside the building without any problems, then also reduce the temperature and maintain visibility in the room to make the job of firefighters easier. To prevent poisoning, an analysis is also needed to remove the “deadzone” or area at a very low speed that has the potential to collect toxic gases in the area.

In addition to extreme conditions such as the fires described above, the presence of vehicles that are ignited when parking or in and out of parking spaces will also emit gases that are quite dangerous if accumulated in an enclosed space. These harmful gases generally include carbon monoxide (CO), nitrogen oxides (NOx and sulfur oxides (SOx).

The concentration of CO will produce the highest threat, resulting in very dangerous side effects and even death. This gas has no color but can very quickly poison humans before realizing there are indications of poisoning symptoms. CO poisoning is the most common and fatal event of air poisoning. If the air ventilation design in the space is not sufficient, poisoning and even death may occur.

The following is the concentration of CO in the air based on various international standard data:

- 200 ppm: Maximum exposure limit 15 minutes (source: NIOSH)

- 50 ppm: Maximum limit of workers exposed for eight hours (source: OSHA)

- 50 ppm: Recommended activation of mechanical ventilation in indoor parking lots (source: UMC)

- 35 ppm: Recommended < 35ppm for ambient air for one hour (source: EPA)

- 35 ppm: Maximum concentration for workers for eight hours (Source: NIOSH)

- 25 ppm: Maximum concentration for workers for eight hours (source: ACGIH)

- 25 ppm: Recommended activation of mechanical ventilation in indoor parking spaces (source: IMC)

- 9 ppm: Recommended ambient air concentration for more than eight hours (source: EPA)

ASHARAE highlights CO emission is one of the most focused on a parking lot design. For indoor parking lot, ANSI/ASHRAE Standard 62, “ventilation for acceptable indoor air quality”, recommends 9 ppm maximum for eight hours and 100-200 ppm for short periods of time. In general, the control of these gases is to use an external air supply, exhaust fan, blower and ducting.

Based on the explanation above, as a parking space designer, we must also consider good ventilation for the safety of its users. However, the design of the parking lot sometimes has to adjust the existing space so that we cannot easily analyze it based on previous experience because the data may be different. Then we have to deal with the design of the existing room with the safest solution but must still pay attention to the budget from the installation of exhaust, ducting, fans and others.

To do this, a very powerful method has been developed to analyze a room with any kind of model and configuration using a computational method with a computer, which is also known as Computational Fluid Dynamics (CFD). This method has been widely used by engineers for various fluid analysis purposes, including HVAC and of course the design of this parking space ventilation. This method is quite famous because of its capability that is not only able to predict air flow, but can also calculate air velocity, temperature, and even the concentration of certain gases at each point in 3-dimensional.

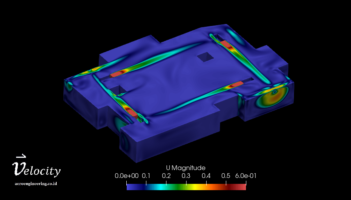

The following is an example of an analysis of a blower installation in a simple parking space:

The above simulation was made using OpenFOAM CFD software. Based on the simulation results above, we can predict which areas have high wind speeds, the “deadzone” area, and predict the concentration of gases in the room, moreover we can very easily move the location of the blower, exhaust, ducting and others with the help of a computer and predict the results of these configuration changes. Using the CFD method, we are able to understand the design problems deeper.

Leave a Reply

Want to join the discussion?Feel free to contribute!